One of the most compelling use cases in IoT is in the area of Asset Tracking and Management. Asset classes can range from living, nonliving, transitory, stationary, remote to the accessible. An Asset Tracking system designed for one asset class can rarely be redeployed for another asset class as is. Each of the use cases and application scenarios are different and unique.

A further challenge to the emergence of a single dominant platform for managing assets is the heterogenous nature of assets that firms typically employ, even within the same industry. Therein lies the challenge of developing an Asset Tracking system; necessitating a multifaceted approach across various disciplines.

Wastage in Businesses – Inefficiency or Cost of Doing Business?

Every year businesses across all sectors of the economy lose billions of dollars on account of the following:

- Excess Inventory on hand.

- Low Asset Utilization and/or Asset Loss.

- Non-identifiable, Non-trackable and Perishable supplies.

- Labor costs associated with idling and/or unnecessary hauling of equipment.

- Line stoppages and business interruptions due to missing supplies and/or equipment breakdown.

- Cost of expediated transportation.

The above challenges need a systemic approach to tackle the inefficiencies, but you can’t fix what you don’t know.

Asset Tracking System: A Strategic Imperative

Activist investors are pressuring mismanaged firms to undertake a strategic review of how their businesses are run. During the 2017 proxy season, activists launched 327 public campaigns against U.S. companies, with $121 Billion1 under their management. Firms needs to proactively identify areas of weakness in their sphere of activities and call for a course correction.

Here are a few examples where the use of Asset tracking can unleash hidden value, eliminate waste and increase overall efficiency:

- In Los Angeles and Long Beach, California home to the busiest container ports in the USA, average truck turn time is around 82 minutes.2

- According to a 2017 study by National Retail Federation U.S. businesses lose around $50 billion annually to retail shrinkage.3

- Transportation delays in-transit and on customer premises will cost US chemical manufacturers an additional $22 billion in working capital on account of additional inventory held.4

- Annually hospitals lose 20% of their equipment. Historically asset utilization in US Hospitals has stayed around 40 percent, which means valuable assets such as IV pumps sit idle 60 percent of the time.5

- In the USA, an average city water utility loses 30 percent of the water supplied through leaks or un-billed usage.6

Asset Tracking System: A Competitive Advantage

The Internet has played an important role in the creation of new products-ideas, their diffusion and in levelling the playing field across firms and industries. Gone are the days where quality management systems such as TQM and Six Sigma enabled firms to leap frog competition.

The basis for competition in the hyperconverged world relies on achieving better quality with greater agility, easier provisioning and lower administrative costs. It’s imperative for firms to adopt a system wide view of their activities from procurement, design, manufacturing, operations, delivery, installation to use.

A firm that can leverage enterprise knowledge, integrate best practices and leverage asset tracking data can acquire a competitive advantage over its rival. To get there, firms need to invest on a platform that can leverage multiple data points and in-house knowledge to unlock hidden value.

Asset Tracking: Passive, Active or Intelligent?

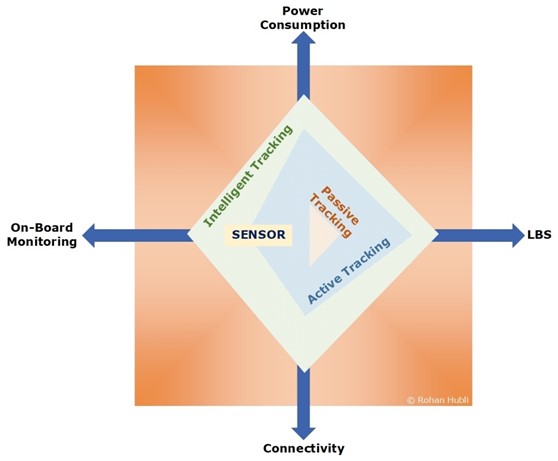

At the basic level passive asset tracking involves nothing more than an electronic label and reader (e.g. RFID, NFC). One level higher is Active Tacking which entails connectivity, LBS (Location Based Services) and some form of a sensor coupled to a power source.

An intelligent asset tracking solution adds an extra layer of complexity with On-Board Monitoring, of one or more parameters of interest. Applications that require Real-Time resolution can now handle extreme events and undertake preventative actions.

Asset Tracking and Management – The Six Critical Elements

A compelling Asset Tracking solution requires the delicate act of balancing six critical elements – Sensors, Location Based Services (LBS), Connectivity, Power Consumption, On-Board Monitoring and Analytics.

- Sensors: The one analogy that I can think of when it comes to sensors is blood. Like blood, sensors serve three main functions: convey, protect and regulate the asset under observation. Sensors comes in all shapes, forms and functions the choice depends on what one intends to monitor, control and prevent.

- Location Based Services (LBS): For assets confined within a certain geographic radius (e.g. hospitals, warehouses, factory floor) one can assign fixed location identifiers or use triangulation (aided by beacons) to pinpoint location. If the asset under consideration involves a moving target (e.g. trucks, drones, mining equipment, shipping containers) that requires real-time monitoring one can select GPS or A-GPS (lower battery drain).

- Connectivity: The choice of connectivity often boils down to the tracker location (local vs. remote) and mobility (stationary vs. transitory) constraints. Additional requirements stem from network reach and coverage – PAN, LAN, MAN or WAN. The choice for a reliable connection range from NFC, Bluetooth Low Energy (BLE), ZigBee, ZigBee-IP, IEEE 802.11ah, WLAN to LPWAN (SigFox, LoRa, RPMA, Symphony Link, Weightless, NB-IoT, LTE-M). To offset some of the limitations arising out of cost, security and low power consumption gateway devices are often deployed for last-mile connectivity.

- Power Consumption: One of the key design metric in deploying trackers is whether to be battery or grid powered. For remote or unreachable applications, the choice is often forced. Additional constraints that dictate power usage include -Always ON, Alive When Spoken To and Periodic Awake.

- On–Board Monitoring: Applications that demand real-time monitoring have an additional constraint: take preventative or corrective actions before it’s too late. In battery powered devices there is a critical requirement to eliminate redundant data transfers or aggregate sensor readings. Both these scenarios call for an On-Board monitoring system.

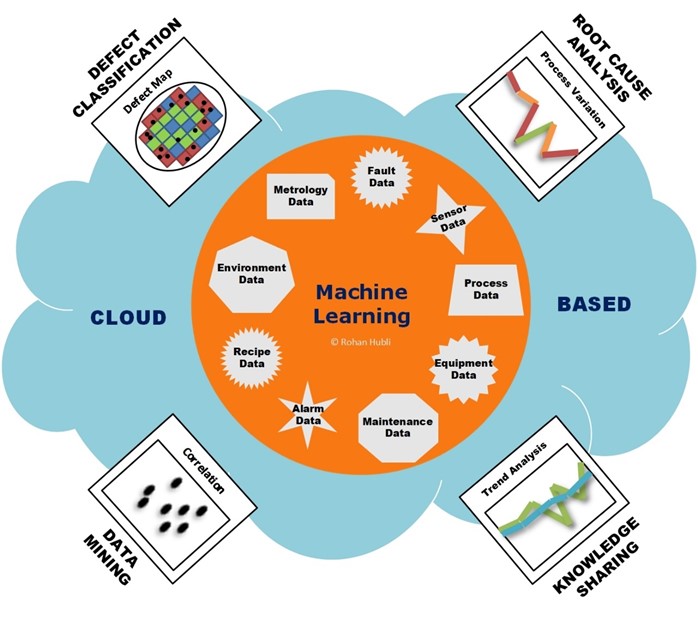

- Analytics: What good is any data if you can’t act on it. The real value in any asset tracking system is knowing how to develop real-world solutions based on the insights gathered. The applications are numerous but just to list a few – Overall Equipment Efficiency, Defect Monitoring & Classification, Predictive & Preventative Maintenance, Trend Analysis and the holy grail using Machine Learning and AI to uncover hidden value.

A follow-on post will look at how various technologies can be leveraged and integrated to build a solution from ground up, specifically for the trucking industry.

References:

- The 2017 Proxy Season, Published by J.P. Morgan’s M&A Team, July 2017

- Average Monthly Truck Turn Time, Harbor Trucking Association, 2015-2017

- National Retail Security Survey 2017, NRF

- Transporting growth: Delivering a Chemical Manufacturing Renaissance, American Chemistry Council, March 2017

- Industry Survey: Transformative Technology Adoption and Attitudes—Location Technologies, ABI Research, 2Q 2017

- Smart Water Network, Navigant Research, 2016

- Prince, Jeffrey and Simon, Daniel H., Has the Internet Accelerated the Diffusion of New Products? (April 1, 2009).

Acknowledgements:

In fond memory of Rev Fr. Agnelo Pinto and Rev Fr. Pat D’Lima whose guidance during my adolescent years at St Paul’s High was instrumental in shaping who I am today.